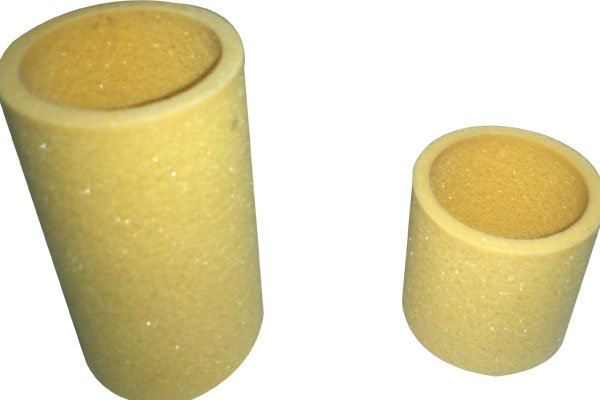

Sintered Filter Element Manufacturer

We, Ami Enterprise are the foremost Sintered Filter manufacturer and supplier in Ahmedabad, Gujarat, India. We provide the best filter that is fabricated and designed by our skilled professor with highly advanced knowledge using the quality approved raw materials. It also named metal porous sintered filter is made of stainless steel or titanium powder and stainless steel filter cartridges suitable for use in a wide range of industries, including petrochemical. It is an advanced type material for filtering. It has strong heat stress and vibrating load and can operate in high temperatures and in a corrupted medium. It may be welded, felted and mechanism machining, and may be regenerated after dirty. They are suggested for the filtration of air or fluids at higher operating temperatures and corrosive environment.

They are fashioned by cold is static pressing, which gives high porosity to the material and improves its steadiness. They can be easily cleaned or back washed, which makes it longer working life. On comparing other metal, filters gives an outstanding strength, anti-corrosion property and long services. It is an ideal choice for backwash filtration, high temperature and harsh environment applications. It can be cleaned and is reusable. It has the advantages of high mechanical strength, high temperature resistance and good corrosion resistance, etc. By adjusting the powder element size, we could construct it with a broad range of filtration accuracy. Compare to other types of filter materials, such as stainless steel wire mesh, Melt Blown Filter Cartridges, Duplex Basket Filter, Fuel Pump Filter, String Wound Filter Cartridge Manufacturers, ceramics, glass fibers, filter paper, Ami Enterprise sintered filter element have higher mechanical and compressive strength. No matter in extremely high and low temperature experience, our filter elements will provide you excellent filtration performance

Advantages

- Simple forming, machining, welding and cleaning

- High strength for cleaning and use multiple times

- Custom service for wide range of material and dimensions

- Commonly used in-200℃ ~ 650℃and acid, alkali corrosion environment