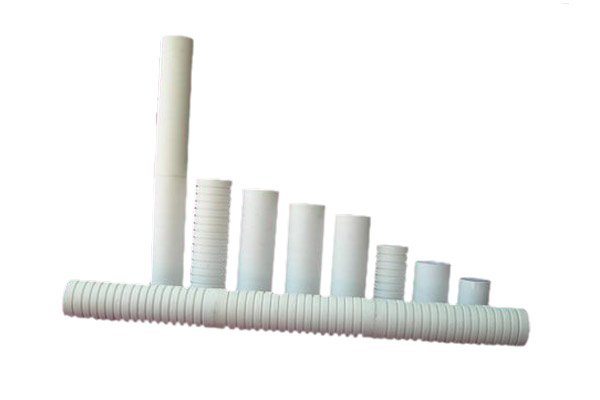

Leading Supplier & Manufacturer of Resin Bonded Filter Element, Liquid Filters and Cartridges, Resin Bonded Filter Cartridge at Best Price in India

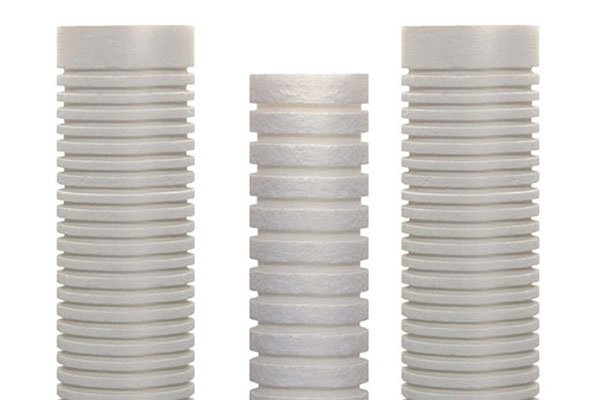

Resin bonded cartridge filters feature an advanced manufacturing process that produces an extremely rigid graded density structure that allows the filter to withstand extreme viscosity and temperature without deformation or collapse In addition, a true graded density structure allows complete utilization of the filter depth, with larger particles captured in the outer zone and finer particles captured in the inner qualifying zone. The grooved construction helps to increase the effective surface area of the filter there by reducing the clean differential pressure and increasing the dirt holding capacity of the filter, Resin Bonded Filter Cartridges. The RIGID Structure ensures consistent reproducible performance free from bye-pass and unloading